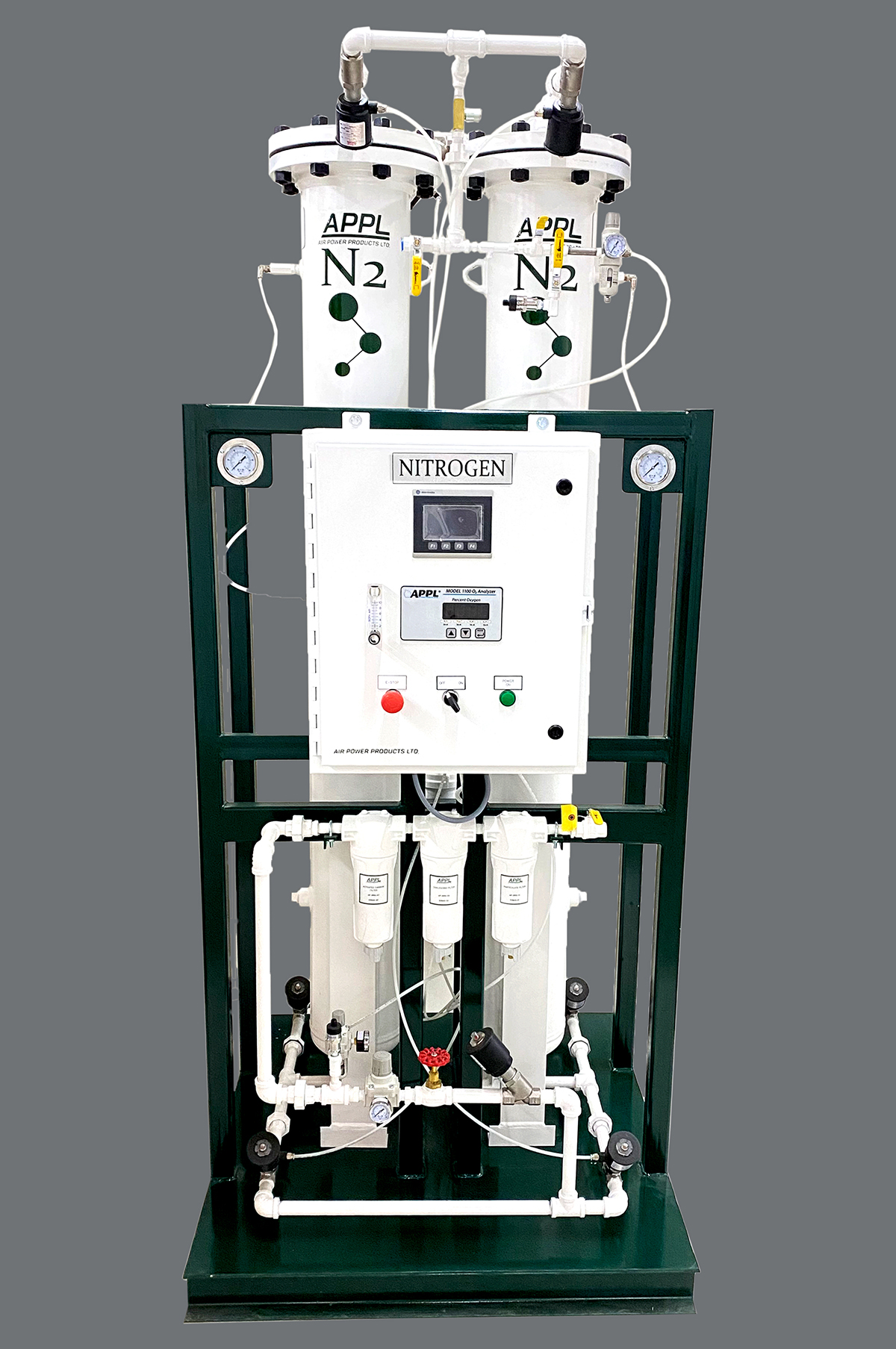

PSA Twin Tower & Modular Nitrogen Generators

Different Industries One Solution

Pressure & Dewpoint

Working pressure up to 150 PSIG & dew point (– )40 °C and lower.

Higher pressures up to 10,000 PSIG can be achieved with booster compressor.

Energy Efficient

Power consumption starts at 0.2KW/m3/35 cu.ft

Approvals

How it Works

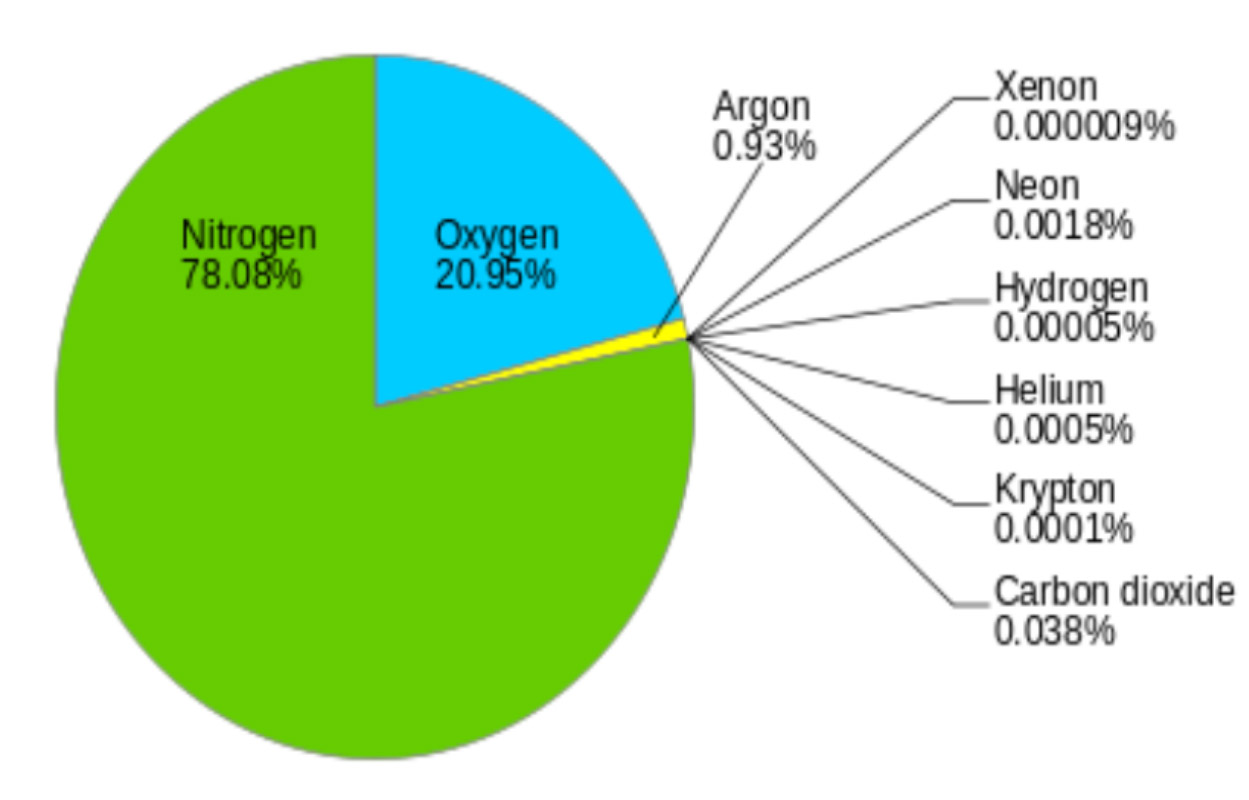

The air in earth’s atmosphere is made up of approximately 78 percent nitrogen and 21 percent oxygen. Air also has very small amounts of lots of other inert gases too.

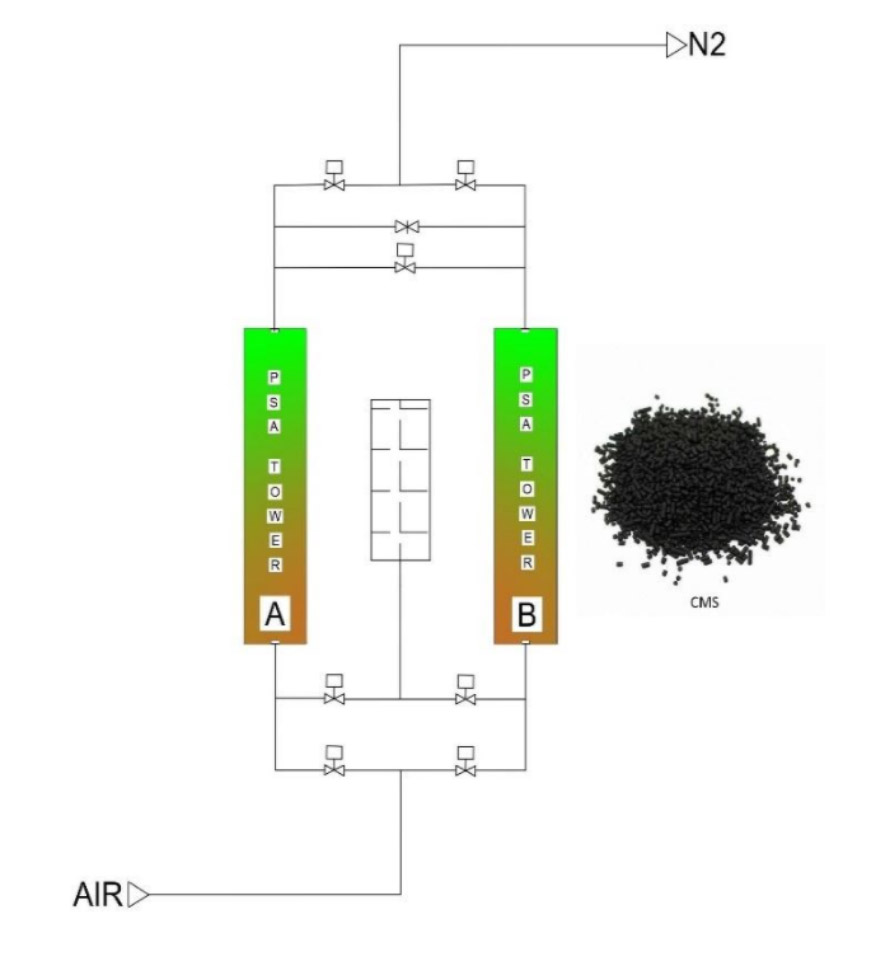

Pressure swing adsorption (PSA) process consists of two or more absorber beds filled with high purity carbon molecular sieves (CMS). In this process, air is sucked from atmosphere & compressed at about 100-150 PSIG using lubricated screw or reciprocating compressor. Air is then treated with dryer to remove excessive moisture and then passed through set of coalescing and activated carbon filters to make it moisture & oil free before it enters the adsorber bed filled with CMS.

Carbon molecular sieves (CMS) inside the adsorber bed selectively adsorbs O2, H2O & CO2 molecules present in the air stream and allows pure Nitrogen to be collected as product gas at the outlet.

Two or more adsorber beds alternate at equal intervals to produce nitrogen continuously and adsorbed gases are released back to the atmosphere.

Custom designed and packaged in North America.

Benefits of onsite gas generation

- Very cost-efficient & fastest ROI

- Provides increased process safety

- Environmental friendly

- Reduces downtime & supply chain issues

- Fits to process/project-specific needs

Applications

Tire Filling (Automotive, mine trucks, aircrafts)

Food and Beverage Packaging

Beverage Industry

Grain Storage

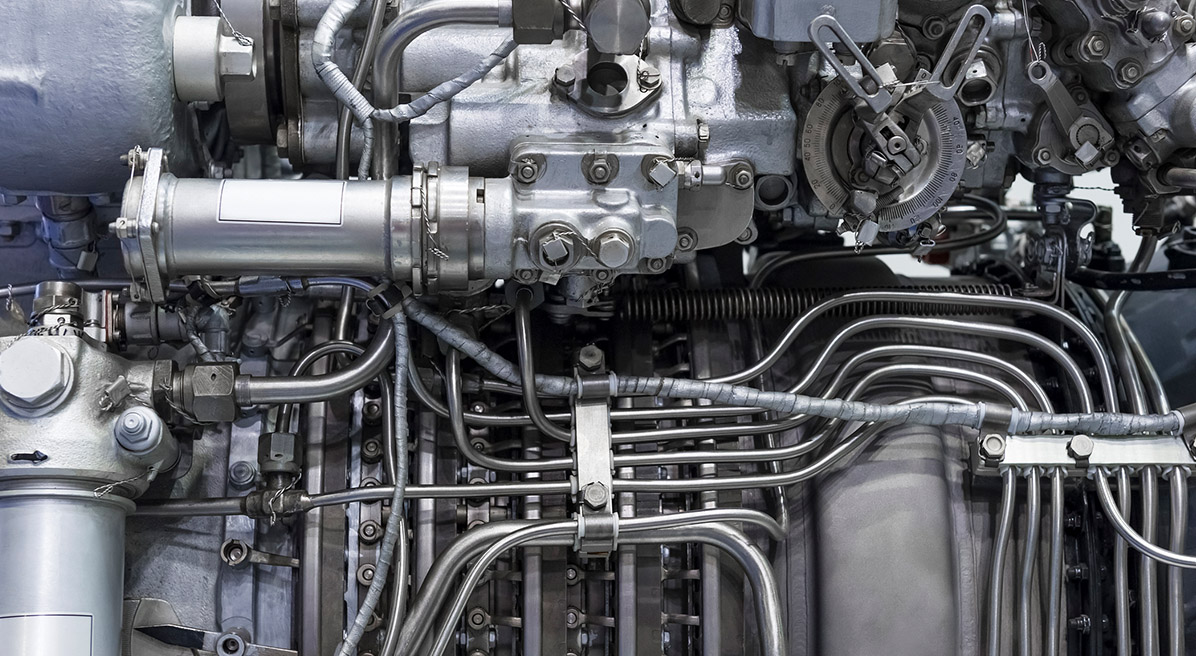

Fuel/Chemical Tank Inerting (Petrochemical & Chemical)

Pharmaceutical

Metal Processing

Fire Prevention

Oil & Gas

Laser Cutting

Shipping & Storage

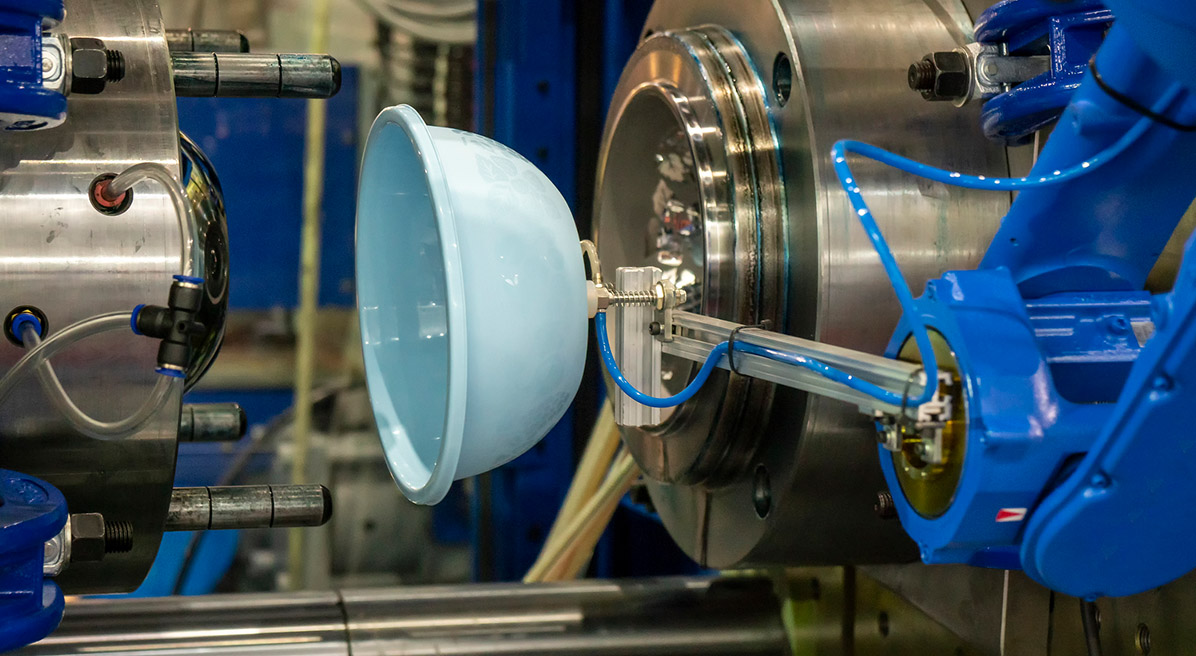

Injection Molding & Plastics

Leak Testing & Flushing

Produce Storage

Power Plants