Onsite O2 Gas Generation

Different Industries One Solution

Product key features

- Provides uninterrupted oxygen gas supply 24/7

- Power consumption at less than a kw/m3/35 cu.Ft.

- Very low maintenance & compact system footprint

- Competitive price, best roi & quick delivery

Popular industrial applications

- Oxygen gas supply for hospitals Fish farming

- Waste water treatment

- Glass manufacturing

- Pulp & paper manufacturing

- Battery manufacturing

- Chemical oxidation

Approvals

Product Features

- Carbon steel adsorber vessels

- System piping in stainless steel/copper/brass

- 3 Stage inlet airline filtration

- Industrial duty stainless steel angle seat valves

- Complete system assembled on a steel frame

- Inlet air pressure transmitter

- Outlet oxygen pressure transmitter

- Inlet air pressure regulator Pressure gauge for individual adsorber vessel

- Asme safety relief valves

- Compact solenoid valve manifold Panel mounted oxygen analyzer ( % )

Power supply voltage 110-220 vac/1/60 or 24 vdc

Optional 4-20 ma signals for purity/pressure/flow

Advanced plc & hmi to manage system operations

Built in hour meter to monitor maintenance

Low inlet air pressure alarm

Low outlet oxygen pressure alarm

Oxygen low alarm

Airline filter element change notice/alarm

Data logging for purity, pressure & flow

Optional ethernet & modbus communication

How it Works

Principle of Selective Permeation for Gas Seperation

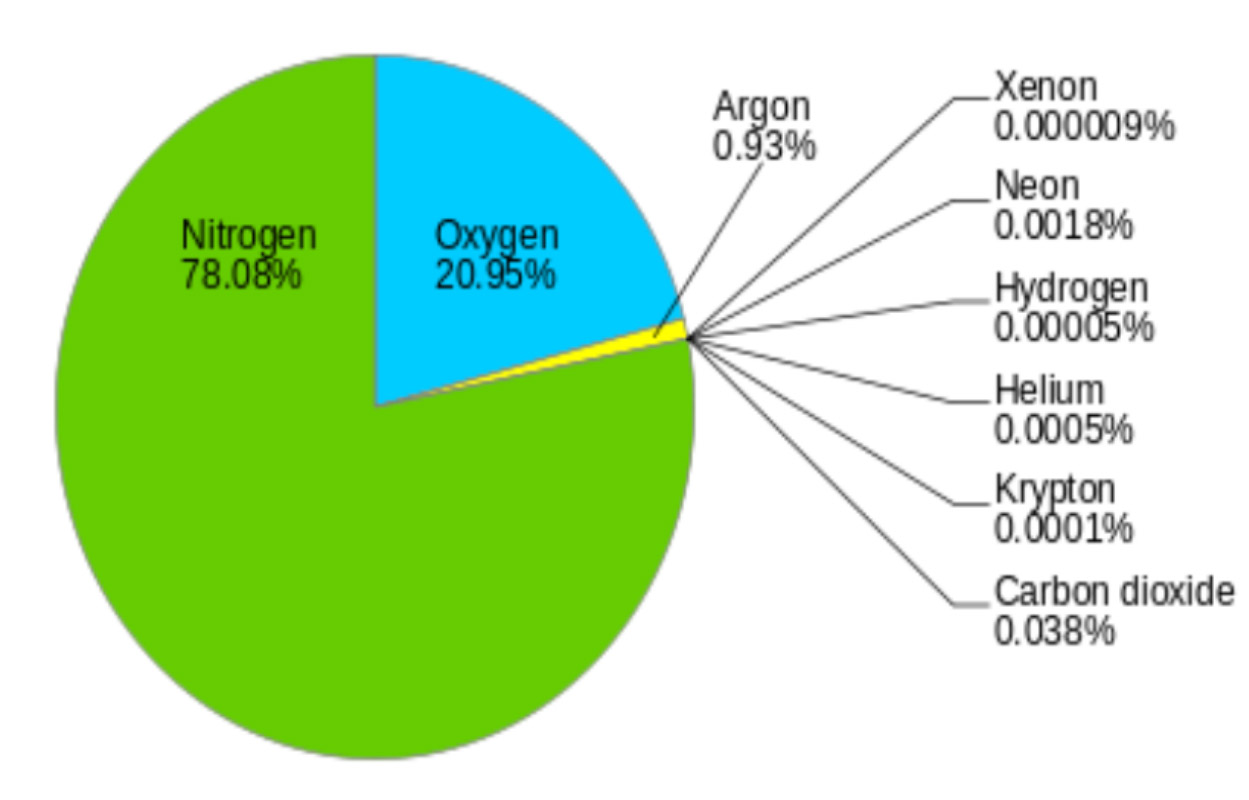

The air in earth’s atmosphere is made up of approximately 78 percent nitrogen and 21 percent oxygen. Air also has very small amounts of lots of other inert gases too.

Gas separation membranes work according to the principle of selective permeation through the membrane surface. The permeation rate of each gas depends on its solubility in the membrane material and on the diffusion rate of the gas.

Gases with high solubility and small molecules such as oxygen, Co2 & water vapour pass through the membrane very quickly & permeate through the fibre walls. Less soluble gas such as Nitrogen with larger molecules takes more time to permeate the membrane, as a result enriched Nitrogen exits as product gas. In addition, different membrane materials separate differently. The driving force needed to separate gases is achieved by means of a partial pressure gradient.

Benefits of onsite gas generation

- Very cost-efficient & fastest ROI

- Provides increased process safety

- Environmental friendly

- Reduces downtime & supply chain issues

- Fits to process/project-specific needs