Membrane Nitrogen Generators

Different Industries One Solution

Flow Rates & Purities

System Purity Range: 95 % to 99.5 %

Flow as low as 40 SCFH and there is no upper limit to the flow rates. Systems can be custom designed and packaged as per your flow and purity requirements.

Pressure & Dewpoint

Working pressure up to 362.5 PSIG & dew point as low as -80 °C

Higher Pressures up to 10,000 PSIG can be achieved with Booster Compressor

Approvals

How it Works

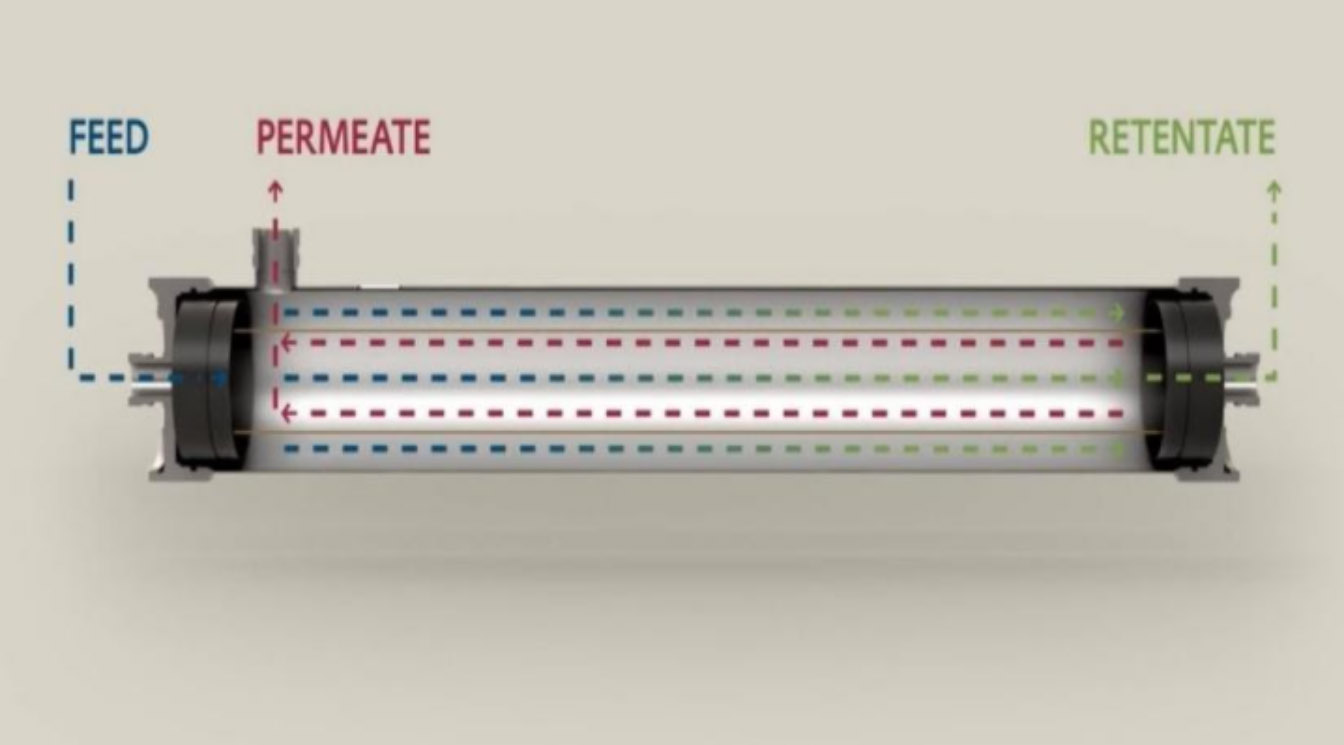

Principle of Selective Permeation for Gas Seperation

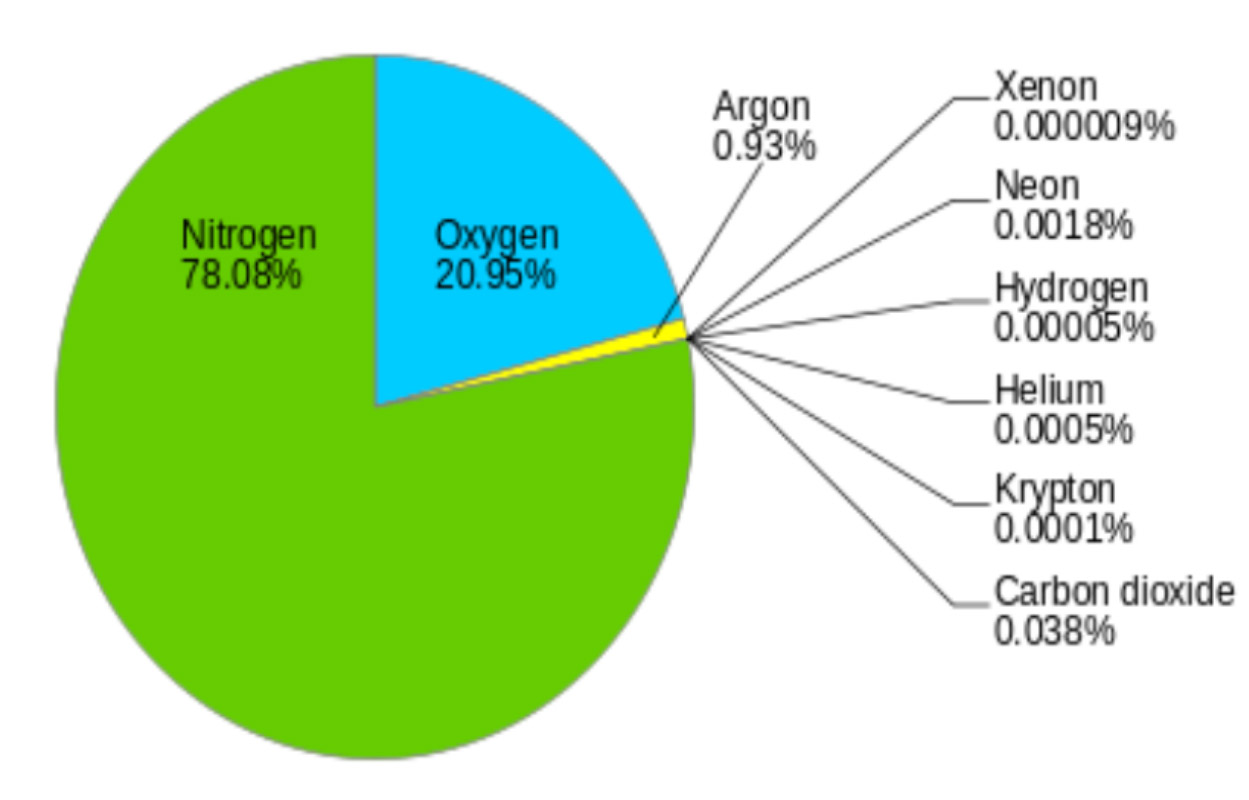

The air in earth’s atmosphere is made up of approximately 78 percent nitrogen and 21 percent oxygen. Air also has very small amounts of lots of other inert gases too.

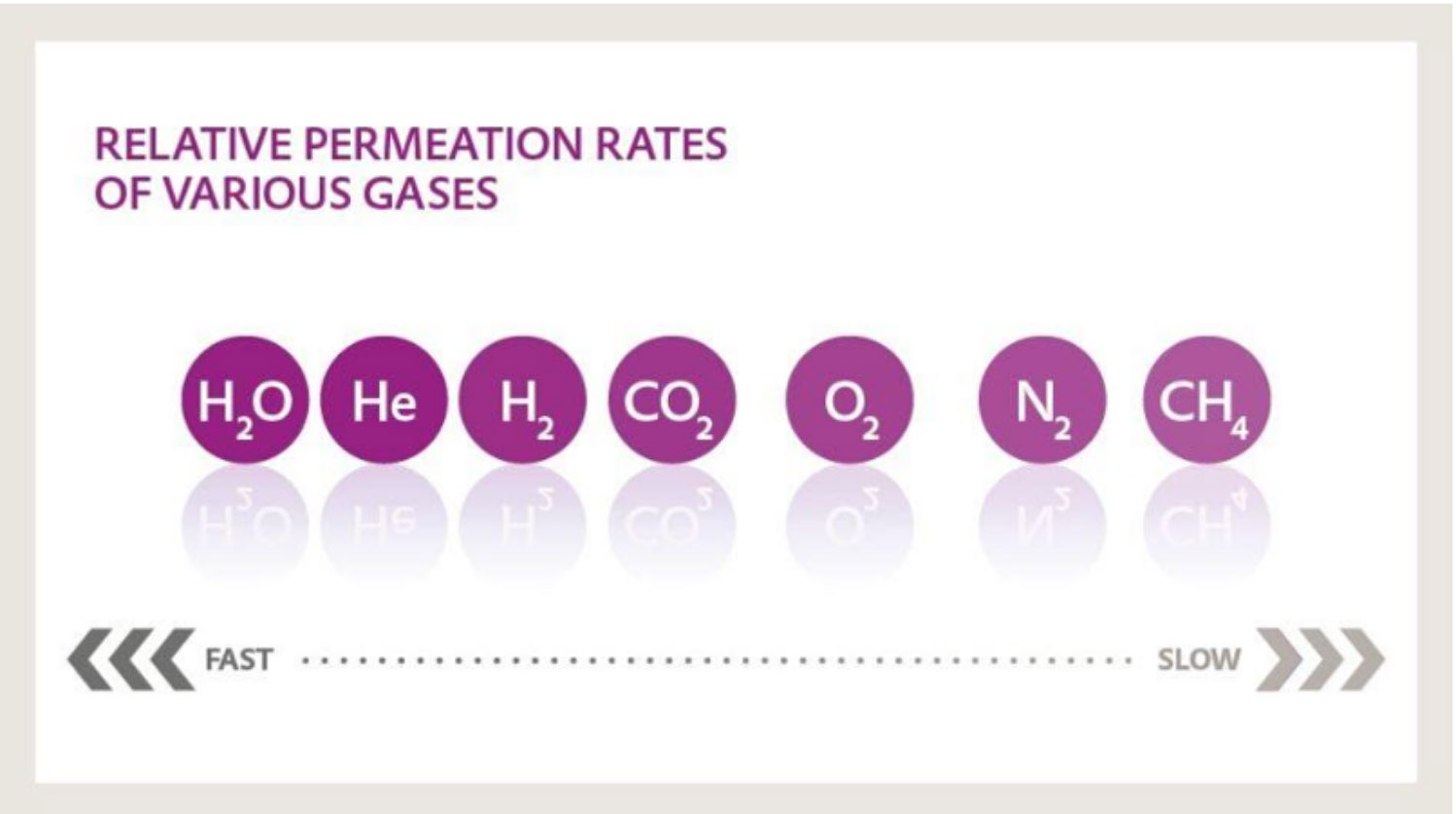

Gas separation membranes work according to the principle of selective permeation through the membrane surface. The permeation rate of each gas depends on its solubility in the membrane material and on the diffusion rate of the gas.

Gases with high solubility and small molecules such as oxygen, Co2 & water vapour pass through the membrane very quickly & permeate through the fibre walls. Less soluble gas such as Nitrogen with larger molecules takes more time to permeate the membrane, as a result enriched Nitrogen exits as product gas. In addition, different membrane materials separate differently. The driving force needed to separate gases is achieved by means of a partial pressure gradient.

P & ID Examples

Benefits of onsite gas generation

- Very cost-efficient & fastest ROI

- Provides increased process safety

- Environmental friendly

- Reduces downtime & supply chain issues

- Fits to process/project-specific needs

Applications

Tire Filling (Automotive, mine trucks, aircrafts)

Food and Beverage Packaging

Beverage Industry

Grain Storage

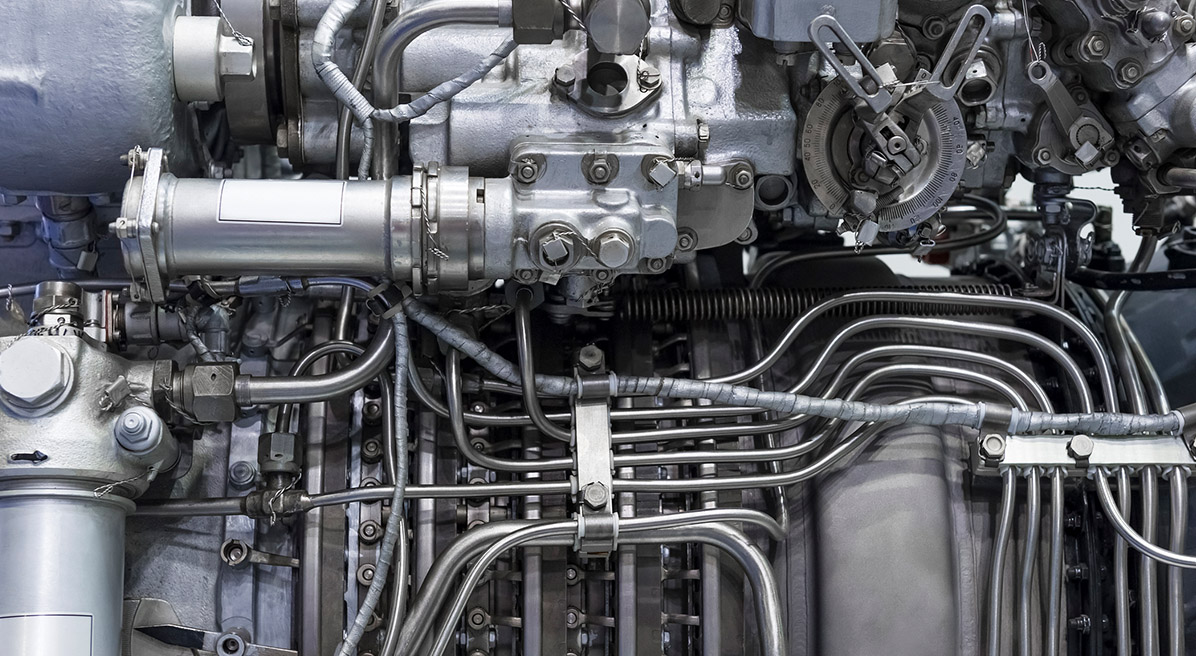

Fuel/Chemical Tank Inerting (Petrochemical & Chemical)

Pharmaceutical

Metal Processing

Fire Prevention

Oil & Gas

Laser Cutting

Shipping & Storage

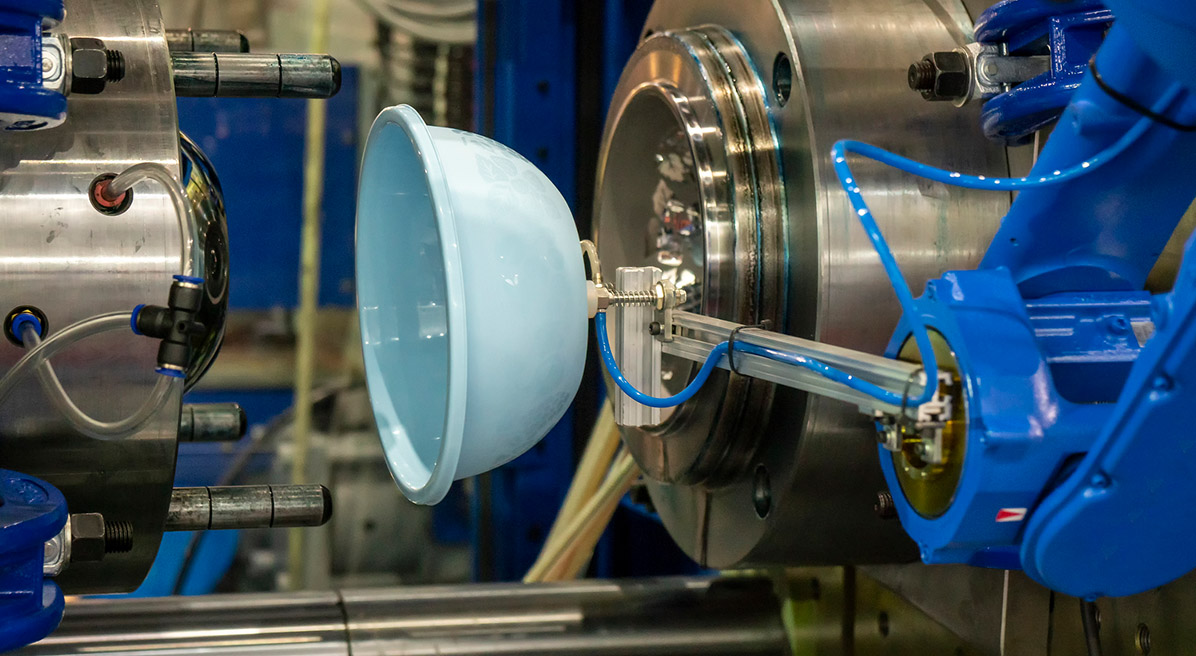

Injection Molding & Plastics

Leak Testing & Flushing

Produce Storage

Power Plants